The Centennial Chalice is being raised from flat copper sheet metal. Raising is the term that describes creating a seamless vessel from flat sheet metal with a hammer (and raising is what we do!).

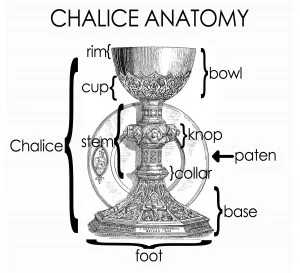

The plan for creating the Chalice involves raising two separate pieces: the bowl of the chalice and the base of the chalice. Once the two pieces are completed, they will be assembled to include a steel node forged from an antique miner's pick and two silver collars forged from 1915 and 2015 minted silver coins. This image shows some basic chalice anatomy to help you imagine the components coming together.

The Chalice we are making does not include all of the elements of this diagram, but the basic anatomy of a chalice is clearly illustrated here. Image from MIR Appraisal Services, Inc.

Though the bowl and the base of the Chalice are raised individually, the techniques used to start the pieces are identical. Last time, we showed you a video of the metal being cut, annealed, and quenched. That process relaxed the metal and prepared it to move willingly with Nile's hammer blows. The next steps taken for both the bowl and the base were to sink the metal, caulk the edge, and finally anneal the metal to prepare it for further hammering. These steps can be seen in the following video.

Sinking is the only step that stretches the metal thinner. This step creates the shallow bowl shape necessary to move on to raising. Caulking is the hammering of the edge of the metal. This step strengthens the edge and keeps it from thinning under successive hammer blows. Annealing is heating the metal. It softens the metal for the next step...

In the raising process, the metal is held at a constant angle above the surface of a specialized anvil called a stake. The hammer drives the metal through the air space created by this angle down against the stake's surface. This compresses the metal and closes it into a more vessel-like shape. It is important to not strike the copper against the stake with the hammer as this will cause weak points in the finished product. It takes many, many rounds of hammering to create a finished vessel! In this video, you are only witnessing one round of raising on the base of the Chalice.

And many, many hundreds of hammer blows later... the Chalice starts to take shape....